A new investment to upgrade resistance limit of PCBs

We are still pursuing our philosophy of continuously improvement aimed to bring about Hi-Tech in production and management spreading it out over each area of our company.

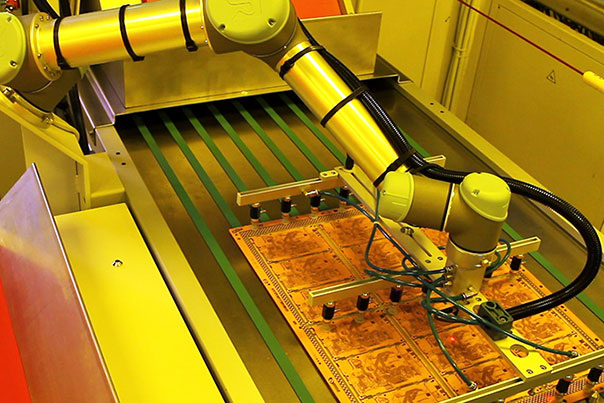

Our last investment has been the installation of a new automatic and robotic line, MECetchBOND CZ, which treats the copper area of laminates used to realize PCBs through a chemical-mechanical process.

This process makes an excellent roughness on copper surface, facilitating endurance of materials which will be posed on it during PCB realization (dry film, liquid film, solder resist).

Several benefits result from it.

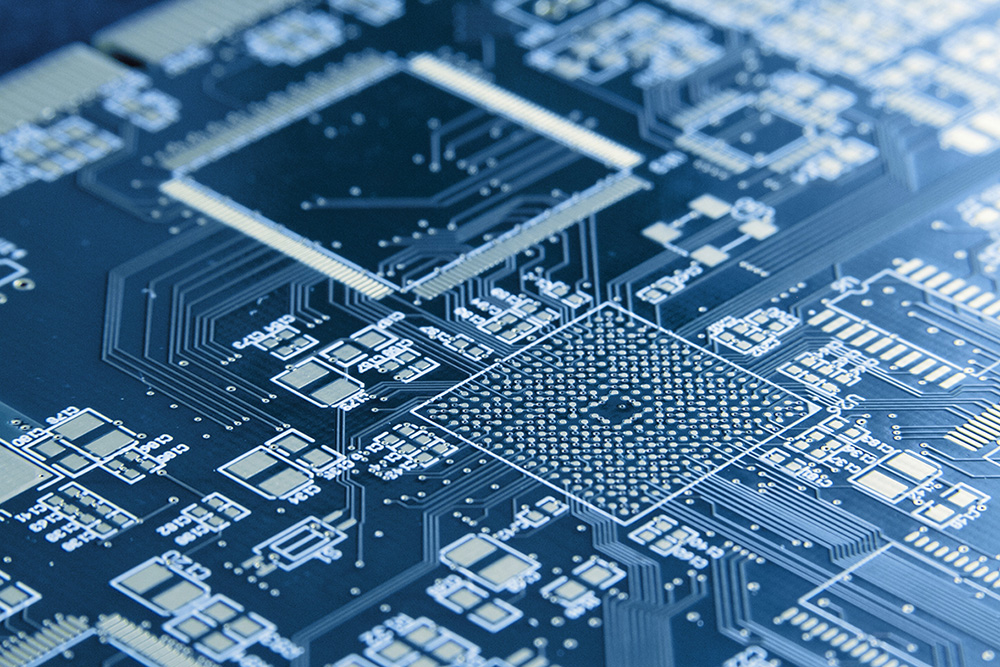

• increase value of endurance to rip of copper track

• improvement of connection among multilayer inners (increases values of endurance to delamination)

reduction of solder mask Peel-off

• reduction of chemical infiltration under solder mask

The utilization of this new line allows to upgrade resistance limit of PCBs.

Andere Beiträge

Fabio Puccia Modica ist neuer kaufmännischer Direktor

Neue kommerzielle Entwicklungsstrategien für ALBA PCB Group. Wir haben uns entschieden, in die Entwicklung unserer...

LESE ALLES

Q-print ist nun Teil der ALBA PCB-Gruppe

Als neuer Teil der ALBA PCB-Gruppe möchten wir die Gelegenheit nutzen, uns bei Ihnen, den...

LESE ALLES

Lötstopplack in Sprühtechnik

Lötstopplack in Sprühtechnik für einen perfekt gleichmäßigen Lötstopplack Eine weitere Investition in neue Technologie in...

LESE ALLES