Crisis: when PCB supplier becomes strategic…

When PCB supplier becomes strategic to manage PCB supplying risks in a crisis situation.

Many companies dealt with efficiency level of their own supplying chain in a crisis situation as that generated from Coronavirus pandemic.

And several companies discovered to entrust to a PCB supplier completely depending on Chinese manufacturers with no strategies to manage a crisis situation as that caused from Coronavirus epidemic. Delays and production stops caused such serious economic repercussions.

Thanks to our Italian production plant and our worldwide organization, we have an everlasting risk management strategy for our customers, helping them to face with this crisis period and avoiding them serious repercussions.

Three essential points:

1) Providing for possible geographic or technical/organizational weakness diversifying production between Far East and Italian one.

2) Planning with customer production for sufficient buffer to face production stop situations or lack in raw material.

3) Intervening with Hi-Tech Italian production plant with contingency plans which prevent production stops to the customer.

Other Posts

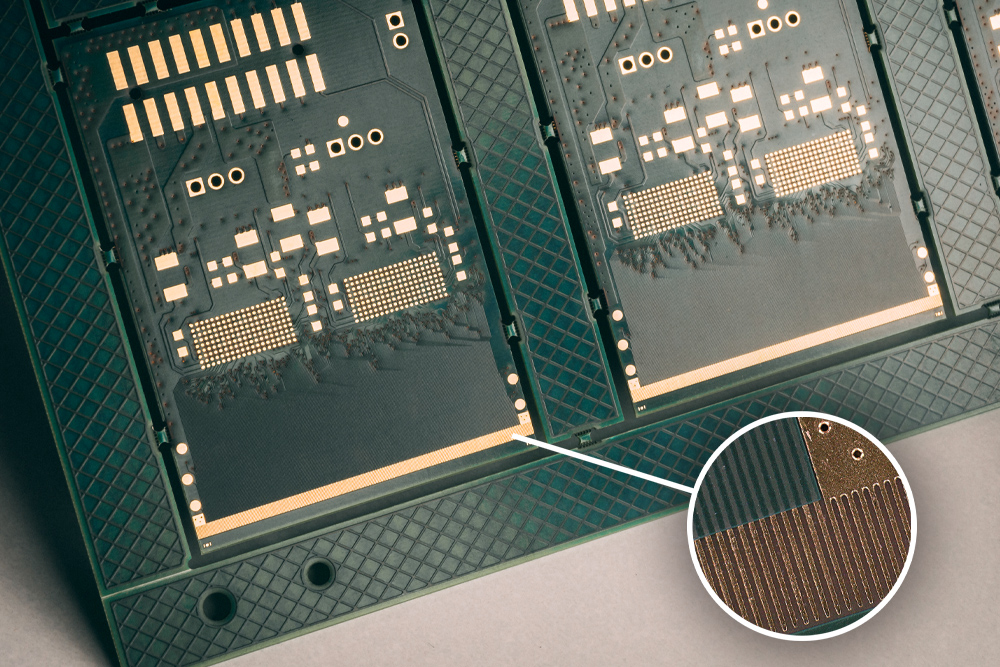

A PCB on the edge of microelectronics

0.11 mm step connector: 70 micron track, 40 micron insulation. The possibility of creating a...

READ ALL

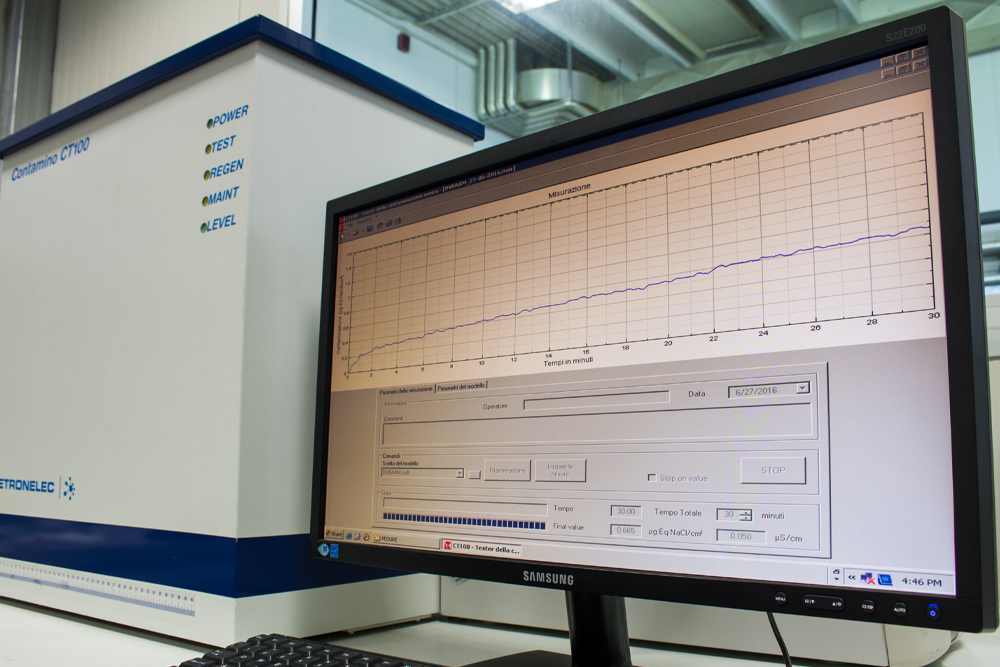

Reduce the ionic contamination of PCBs.

15% of the anomalies on the electronic boards are caused by ionic residues. The ionic...

READ ALL

The new shadow line for a perfect metallization of micro- and blind holes

Fifteen meters of automatic horizontal line for removing all the impurities from the holes, making...

READ ALL