MBB, the pack that protects your printed circuit boards

PCBs are generally made of materials such as glass fibre laminates and epoxy resins, which absorb moisture directly from the environment.

This absorption can cause various problems both during production and in the final use of the PCB, especially if it is a multilayer or if it is used in critical applications.

If during the production process the control of this moisture value is such that it does not interfere with the final quality of the PCB, during shipment and the subsequent periods of transit and storage, the PCB may be exposed to environmental conditions (i.e. also the microclimate inside the package) which cause it to absorb moisture.

The consequence of this are phenomena that can have consequences during soldering of the PCB, on its subsequent proper functioning and finally on its reliability over time:

• Delamination during soldering: trapped moisture evaporates during the soldering process causing blistering (blistering) and cracking (cracking) on the substrate material.

This mechanical stress can also affect the electrical connections (tracks, pads, hole cylinders). The same accumulated moisture can also generate undesirable outgassing effects again during soldering (“blow out” effect in the joints).

• Reduced wettability: Moisture can easily affect the wettability of the PCB surface finish because it accelerates the formation of surface oxides of the metals on the PCB (where not covered by solder resist).

• Surface contamination: Moisture can facilitate the accumulation of contaminants on the PCB surface. These contaminants can compromise solder quality and reduce the reliability of electrical connections, as well as potentially facilitating the initiation of long-term ion migration phenomena.

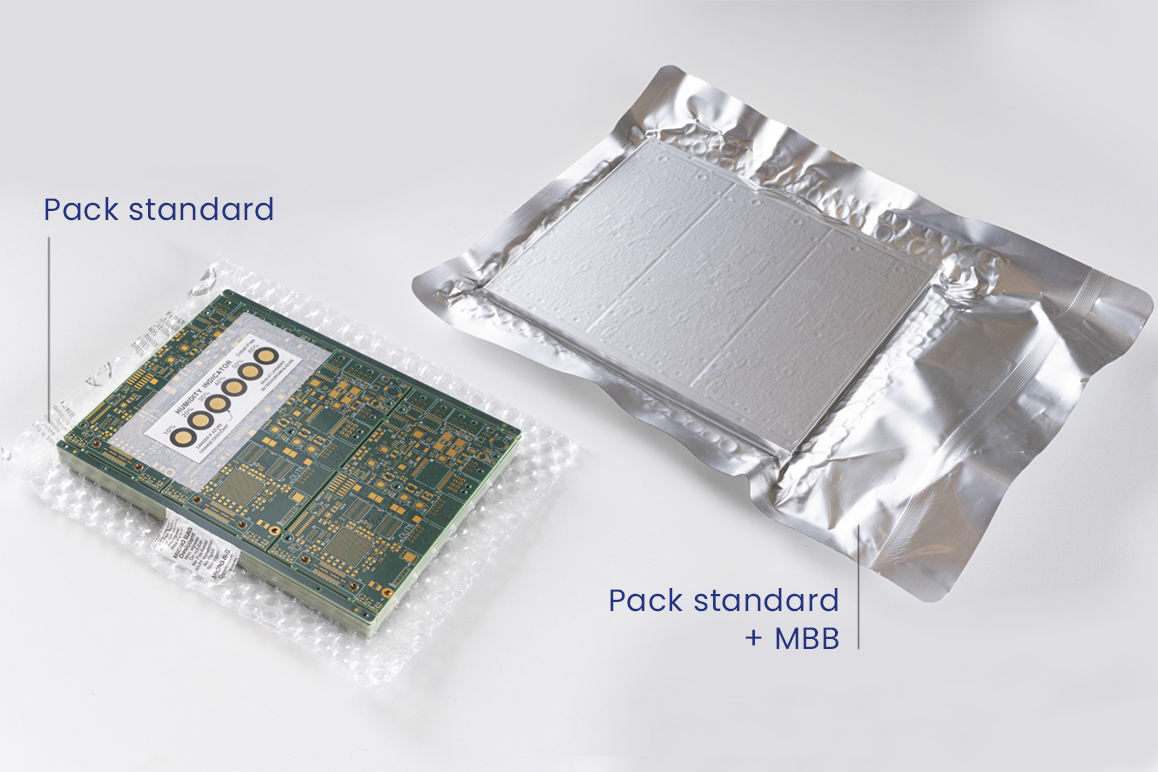

To offer a solution to moisture absorption, we have also added to our packaging formats a solution that secures the PCB using MBB – Moisture Barrier Bag, also in the higher performance version with an aluminised cavity.

The MBB is a packaging designed to protect its contents from both moisture and electrostatic discharge, another factor that can cause undesirable effects in EMS departments.

It is a perfect solution when you want to be sure of almost absolute protection from moisture during transport and long-term storage.

We are available if you need more information.

Other Posts

New line for dry-film removal

The installation of a modern automatic line for the removal (stripping) of dry-film, (an operation...

READ ALL

New line for perfect tin removal (stripping) after etching

The introduction of a new automatic IS tin stripping line at our production plant in...

READ ALL

Alba PCB Group: Eco-Friendly PCB Production with Green Energy

Alba PCB Group has made a choice of respect for the environment, convinced that today...

READ ALL