New line for dry-film removal

The installation of a modern automatic line for the removal (stripping) of dry-film, (an operation that follows the classic galvanic processes of PCB production – Cu electroplating and Sn electroplating) once again underlines our complete focus on the highest quality of the final product and demonstrates our constant desire to keep our production site in Mogliano Veneto (Treviso – Italy) at the forefront of technology.

The line consists of 5 parts:

INPUT MODULE: specially designed and manufactured to allow controlled entry of PCBs that are to undergo stripping treatment in an alkaline solution. The module is equipped with a sensor system to check the presence of the PCBs.

STRIPPING MODULE: consists of a “pre-stripping” section and an “alkaline stripping” section. The chemical solution is sent to both sides of the PCBs by spraying with controlled pressure and temperature regulated by an automatic heating/cooling system.

SUMP FILTER: Technically, the purpose of the Sump Filter is to collect the exhausted residues of the chemical solution used for the stripping process enriched by the “dissolved” dry film in specific containers placed in a special removable trolley and the recovery of the reusable treatment liquid by re-sending it back into the process.

WASHING MODULE: in cascade with the stripping module, its purpose is to clean the PCBs by means of an aqueous solution integrated with antifoam.

DRYING MODULE: this is the final part of the line and is made up of two sections: the temperature-controlled drying unit and the output unit consisting of a series of dragging rollers.

The equipment is completed by an automatic Stand By system which, as well as allowing greater flexibility, reduces the average KW used during the working day and decreases line water consumption.

Other Posts

New line to promote perfect adhesion of the intermediate layers of a multilayer

The introduction of the new Copper Oxidation Line from Ocleppo is a choice that goes...

READ ALL

Alba PCB Group: Eco-Friendly PCB Production with Green Energy

Alba PCB Group has made a choice of respect for the environment, convinced that today...

READ ALL

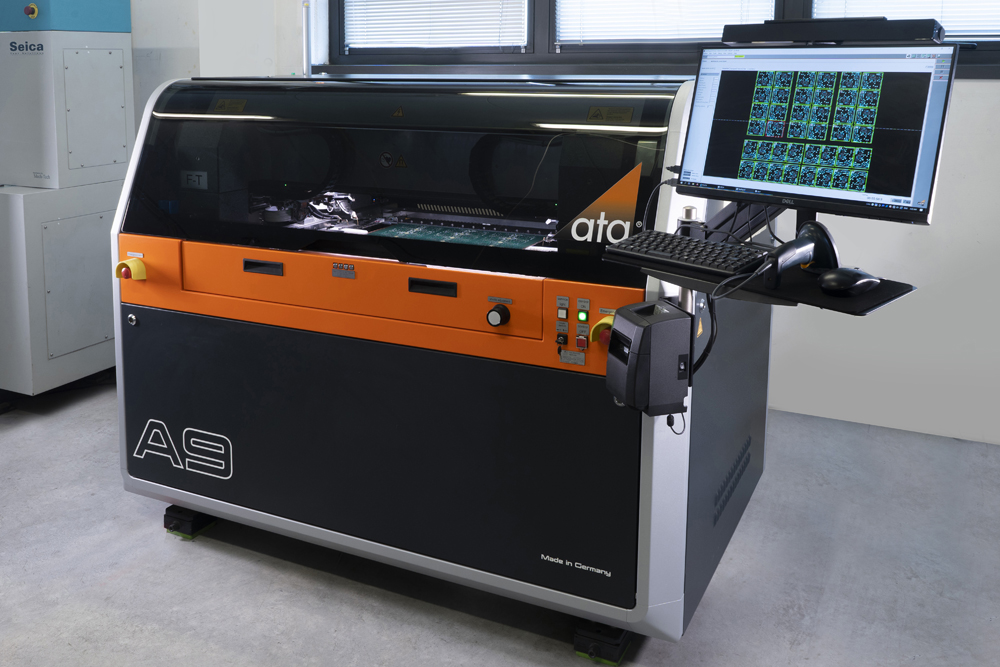

The electrical test flying – the new ATG A9 flying probe

The increasing miniaturisation of electronic boards and the need to test prototypes and small quantities...

READ ALL