New line for perfect tin removal (stripping) after etching

The introduction of a new automatic IS tin stripping line at our production plant in Mogliano Veneto (Treviso – Italy) confirms on the one hand the focus on the quality of the end product and on the other hand the desire to have a plant that is always up-to-date and at the cutting edge of technology.

The purpose of the plant is to optimally remove the electrolytic tin deposited on the PCB during processing. Depositing is done to protect metallised holes and pads during copper etching.

The removal of the tin (stripping) is done in such a way as to leave the underlying copper surface uniform, well cleaned, and of the desired thickness.

With the special washing modules cascading through the line, perfect removal of the chemistry from the surface and holes of the printed circuit board is also ensured.

These conditions are indispensable for the final quality of the PCB in terms of reliability over time.

The line is also equipped with an intelligent Stand By system that reduces the energy impact by reducing the average KW consumption and line water consumption during the working day.

Other Posts

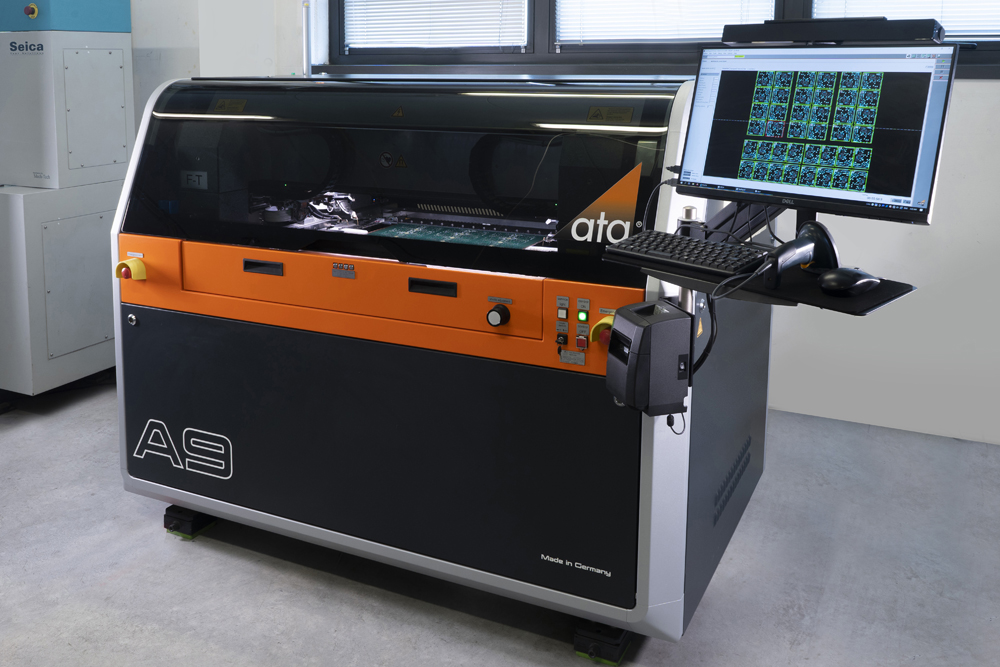

The electrical test flying – the new ATG A9 flying probe

The increasing miniaturisation of electronic boards and the need to test prototypes and small quantities...

READ ALL

Micro-drilling: speed and precision pushed to the limit

In our drilling department, we are at the forefront of production technology: a new Pluritec...

READ ALL

Alba PCB Group: Eco-Friendly PCB Production with Green Energy

Alba PCB Group has made a choice of respect for the environment, convinced that today...

READ ALL